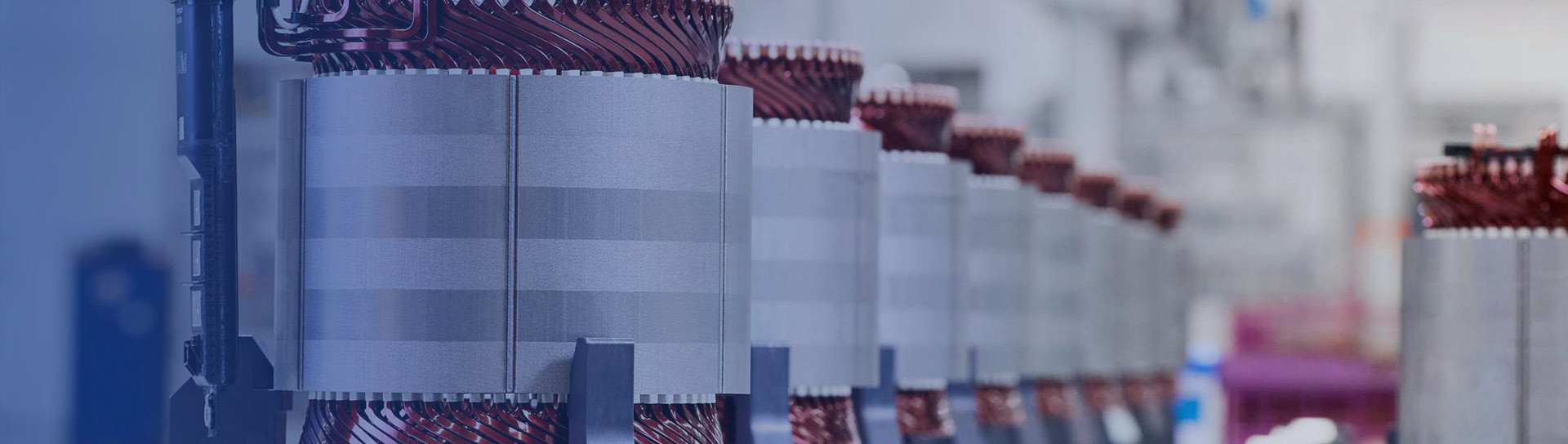

Stator core

The surface treatment process has a stable and smooth structure with no bumps, good stacking coefficient, not easy to corrode and good heat performance.

Product Classification:

Key words:

Punching

Synchronous rotor

- Product description

The surface treatment process has a stable and smooth structure with no bumps, good stacking coefficient, not easy to corrode and good heat performance.

Rotor punch is an important part of the motor, mainly used to fix and protect the rotor coil of the motor, and reduce the friction and wear between the rotor and stator, so as to ensure the normal operation and high efficiency of the motor.

Reduce friction and wear: The rotor punches adjust the position of the rotor in a small range through the friction effect of the static and dynamic rings, reducing the friction and wear between the rotor and stator, thus reducing the energy loss and preventing the motor from overheating and the wear of mechanical parts.

Improvement of motor efficiency: At high rotational speeds, the rotor punches are able to minimize the impact of aerodynamic forces on the motor, increasing the efficiency of the motor and reducing losses and energy waste.

Anti-interference: In some application scenarios, such as model airplanes, precision equipment, etc., rotor punches also have anti-interference effects, which can suppress high-frequency noise and improve the stability and performance of the equipment.

Related Products

Online consultation

Note: Please leave your email address and our professionals will contact you as soon as possible!